Technical Equipment

The following list includes the most important processing machines and plants that are at our disposal:

| ENGINEERING | 12 work- stations | -3 D-CAD -3 D-CAM up to 5-axis simultaneously |

| Number of machines |

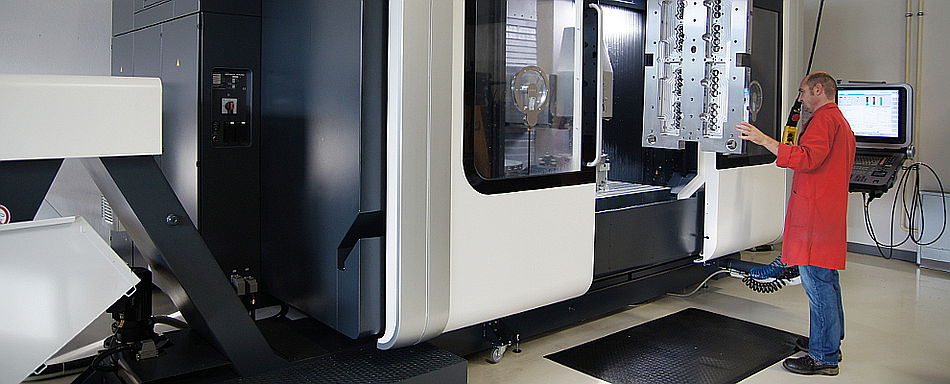

| MILLING | 11 | -processing paths up to 1000 x 800 mm or 1800 x 700 mm -up to 5-axis simultaneously -HSC technology up to min. milling-Ø 0.1 mm |

| LATHES | 6 | -max. Ø 250 mm / max. length 700 mm -Y-axis and driven tools |

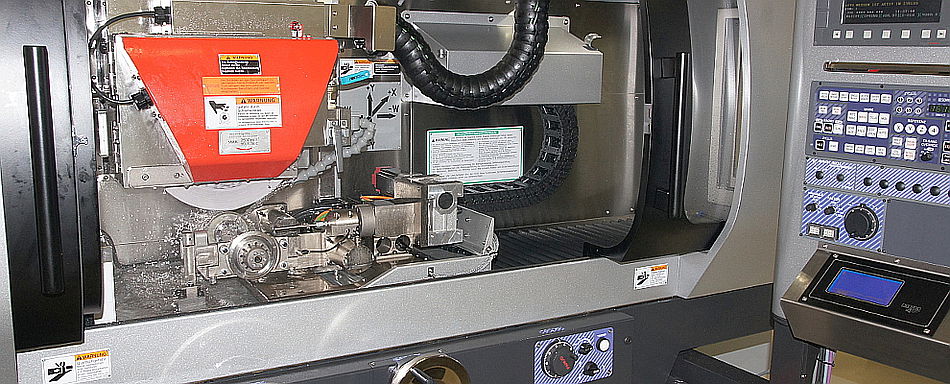

| CAVITY SINKING BY EDM | 4 | -max. processing paths 600 x 400 mm |

| WIRE EDM | 5 | -max. processing paths 600 x 400 mm -Fine wire up to min. Ø 0.03 mm -Processing among others in oil bath |

| EROSIVE DRILLING | 2 | -Electrodes Ø up to min. 0.1 mm -Processing among others in oil bath |

| FACE GRINDING | 5 | -max. processing paths 1500 x 800 mm |

| PROFILE GRINDING | 2 | -max. processing paths 800 x 400 mm |

| PLAIN GRINDING | 4 | -max. centre height 225 mm -max. grinding length 1000 mm |

| JIG GRINDING | 2 | -max. processing paths 450 x 280 mm |

| MEASURING/TESTING | 7 | -tactile up to max. processing path 900 x 700 mm -visual -double flank composite action test -HRC/HRV hardness test and roughness test |

| INJECTION MOULDING/SAMPLE TESTING | 8 | -Clamping forces between 150 and 2200 kN -1K/2K -hydraulic/all-electric |